Production capacities

Production capacities

In order to offer competitive products and equipment in the market, important investments have been made in the production facilities, aligned with the European standards.

By acquiring modern equipment and technologies, we ensure a high level of quality and productivity.

- CNC laser cutting equipment

- CNC plasma cutting and oxy-gas cutting, drilling, threading equipment

- CNC equipment for plasma and oxy -gas cutting of profiles / pipes

- water jet cutting machine

- CNC 5-axis milling machine

- automatic blasting equipment

- painting booth

- flux core arc automatic multitrack welding

- Mig-Mag welding equipment

etc.

These facilities are located in Brasov and cover the following segments:

- manufacturing of industrial cranes, elevators and metal structures;

- forklift truck remanufacture.

Our CNC machining services cover a wide range of operations, including turning, milling, and threading. Depending on the client's requirements, we are ready to provide tailored solutions that meet high-quality standards.

More details: Elmas machining services flyer.

Manufacture of industrial cranes, elevators and metal structures

The modern production plant located in Brasov (Calea Feldioarei 33) is dedicated to the manufacture of industrial cranes (portal cranes, jib cranes), overhead traveling cranes, ELMAS elevators, and metal structures with applications in various industries.

Throughout our production flow, we ensure a high level of quality to generate competitive products that meet our customers' needs, both nationally and internationally.

All products manufactured by ELMAS bear the CE marking that indicates compliance with European standards in the industry.

Remanufacture of forklift trucks

The forklift truck refurbishment line located in Brasov (1y Grivitei Blvd.) involves the re-use of viable, undegradable components resulting from dismantling, testing, and rehabilitation for subsequent reassembly in reliable equipment.

This re-manufacturing process applies only to forklift trucks with advanced stages of degradation, unsaleable, and expired operating life, regardless of whether they are taken from the customer, redeemed, or released from a buyback contract.

This process involves the complete truck dismantling, checking, and replacing the subassemblies and used components, in comparison with a reconditioning phase.

The refurbished forklift trucks benefit from a 2-year warranty/2000 hours and 10-year operating life, service, and spare parts. The product resulting from the re-manufacturing process is intended for sale or rent.

Acest proces de refabricare conduce la o economie de resurse si materii prime, avand un impact pozitiv asupra mediului inconjurator.

This re-manufacturing process leads to a resource and raw material economy with a positive impact on the environment.

NEWS

The Photo Contest 2024, organised by Elevator World, announced its winners

We are honoured that, following votes and the jury’s analysis, ELMAS SRL was ranked first in the “Elevator/Lifts Commercial” category, with the photo “A Point of View”, in the annual photo contest 2024, organised by the US magazine Elevator World.

Roadshow Linde Heavy Truck E100-E180

The Linde Heavy Truck Roadshow took place over two days, according to the schedule:

- May 14, 2024, at the head office in Brașov;

- May 17, 2024, on the premises of the Port of Constanța Sud (Agigea), with the support of Predilect Cargo. company.

Shading system with photovoltaic blinds: green energy and convenience

Elmas’ Research and Development Centre has developed an automated shading system that also generates electricity.

ELMAS elevators – a valuable addition to your building

During 2022 and up to now, ELMAS has innovated and tested a modern design process for cars and call buttons for elevators. It all started with a concept that would ensure a safe use of the elevator, as well as a fashionable and user-friendly car design, both of these experimenting with a technical method. Until now, several such elevators have been completed and are in operation, for testing purposes of the technical process, the design of which has either a theme commissioned by the client, or proposed by ELMAS.

ELMAS was awarded the prize of “Excellence in Circular Economy”

We are honoured that, following a rigorous and transparent assessment by a panel of environmental and sustainability experts, ELMAS SRL was awarded the prize of “Excellence in Circular Economy” for the second consecutive year at the Green Report Gala, which took place on Thursday, January 18, 2024, in the Throne Hall of the National Museum of Art of Romania.

The first long-term elevator rental in Brașov

ELMAS, a company headquartered in Brașov and leader in the field of lifting equipment in Romania, has launched its own rental service for elevators, relying on the premium quality of its products, a core prerequisite for a safe and efficient operation.

Photovoltaic panel system integrated in the Elmas Combiparker auto parking

The automated parking pilot project Elmas Combiparker has entered a new phase: installation of the integrated photovoltaic panel system with multiple functions.

Launching a specialisation course for “Forklift Driver”

With over 32 years of experience in the field of lifting equipment, ELMAS, a company headquartered in Brașov, has launched a specialisation course for “Forklift Driver”, COR code 833403.

The use of green energy in the production flow of lifting equipment

Elmas, a domestic manufacturer of lifting equipment (elevators, industrial cranes, platforms for materials, etc.), invested 4 years ago in its own photovoltaic system. In order to provide the electricity necessary for the production process, the photovoltaic panels were installed on the roof of the hall over an area of 5,000 square meters, with an installed power of 312 Kwp.

ELMAS pilot project - WÖHR Combiparker Automated Parking

In the current context, cities are severely affected by the parking crisis. The number of cars has grown at a very fast pace, posing major problems to the process of urban development. Travelling by car is a necessity, as most of the workplaces are outside the cities, while the homes, the headquarters of the state institutions, the hospitals, the polyclinics, the kindergartens, the schools and the universities are inside the city. In conclusion, there is a need for parking both at home and within the city. ELMAS, the regional specialist in the field of lifting equipment, proposes advanced solutions for the parking place crisis, which can satisfy the needs of the cities.

ELMAS is preparing its new generation of employees

What the students who did their internship and who chose to remain employees of the Brașov company say.

Immersion into Brâncuși's World

The “Bird in The Air” – a creative design combined with a bold, functional and safe concept.

Elmas Brasov budgeted 4 Million Euros this Year for Investments

The Brasov-based company ELMAS, a leader in the field of material handling, planned an investment budget of four million euros for this year, after last year, due to the pandemic, it was forced to stop all significant investments. "Last year we completed the setup works at ELMAS Development and Innovation Center, provided for in the investment of approximately 900,000 euros started in 2019, say the company's representatives.

For the third year in a row, Elmas Brașov ranks first in the “Project of the Year” global competition organized by Elevator World

Elmas Brașov, a company specialized in lifting systems, has won the first prize at the Elevator World “Project of the Year 2021” global competition, the category “Special-Purpose Lifts”, with the project “Pasărea Măiastră - Platform for passengers” for the technical solution proposed.

With a tradition of over 65 years, Elevator World Inc. USA is the publisher of Elevator World, a magazine distributed worldwide to all specialists in the field of elevators. Participation in the international competition “Project of the Year”, in its 23rd edition, is 100% free and open to all elevator manufacturers in the world.

PROFESSIONALISM GIVES RISE TO PERFORMANCE

For the technical solution adopted, Elmas Brașov, a company specialized in lifting equipment, has won for the third consecutive time the Elevator World “Project of the Year 2021” global competition, the category “Special-Purpose Lifts”, with the project “Pasărea Măiastră - Platform for passengers”.

The biggest industrial cranes for loads of 150 and 360 tones, a premiere in the Brasov industry

Specialized in the lifting equipment industry, the ELMAS company from Brasov has signed a contract with an European partner to produce two industrial cranes with load capacity for 150 and, respectively 360 tones.

Winner of Elevator World Project of the Year 2020 with MEGA ELEVATOR

After the success registered last year with the unique elevator from Bran Castle, the Romanian company based in Brasov, ELMAS, was awarded this year as well, at the world competition organized by Elevator World USA, "Special purpose lifts" category, with the lift MEGA ELEVATOR delivered and mounted in Tel Aviv, Israel.

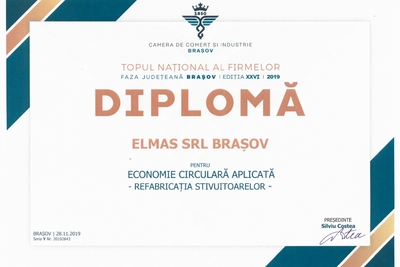

Elmas awarded for the Linde forklift refurbish activity

Elmas Brasov was awarded within the event of the National Top of Companies - the county phase, organized by CCIBV, for the activity of remanufacturing Linde forklift trucks.

Elmas - the official country partner of Demag Cranes&Components

Elmas has been the Official Country Partner of Demag Cranes&Components GmbH in Romania for more than 25 years.

STONE Elevator

A 100% Romanian project, the elevator installed in the Time Tunnel at the Bran Castle, has been recognized internationally, the uniqueness of this model making the jurors of the world contest ”Elevator World”, which was held in the USA, to award it the first prize in the category "Special purpose elevators”. Among the elevators that have entered this world competition and have been awarded in other categories have been models produced by renowned manufacturers from Germany, Great Britain, USA or Japan (Mitsubishi Electric).